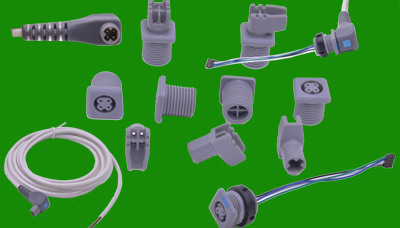

Product Categories

Contact detail

- Mobile Phone:+86 13265562978

- Tel:+86 755-23490966

- Email:sales@fleconn-china.com

Chat Now:

Product Design Services

FLECONN can provide professional product design, research and development services for global clients in the fields of connectors, cable assemblies, metal parts, plastic parts, electronics and electrical components. The concrete services include CAD 2D drafting Services, Proe 3D drawing services, product structure design services, high precision 3D printing services, prototype manufacturing services etc. We can support our customers to complete the design of interconnection solutions, product housing, electronics product encloures, corresponding mould designing and manufacturing, the samples and mass production for components and parts.

Custom Connector Developing

Are you upset about the prolonged product development cycle and long delivery period from international brand connector manufacturers (eg Tyco / AMP, Molex, Amphenol, FCI, Samtac, Phoenix, HARTING, ERNI, binder)?

If yes, we can help you remove these distresses. FLECONN can provide rapid electrical connector development and design, prototype manufacturing and testing. The samples were rapidly presented to you to confirm, thus the new developed connector will quickly enter into mass production. At the same time, your new products also can be launched into market quickly.

Do you feel heartache with the expensive prices of electrical connectors coming from international brand connector manufacturers?

If your purchasing volume is very large, the prices from these first-tier connector manufacturers can not be fallen down and you can also ask us to develop this connector for you. We can develop the connector whose quality is comparable with the original product. Or according to your application, we design the connector that is more in line with the applications of your product, thus it greatly reduces your overall purchasing costs and other potential costs by seeking for cooperating with you.

Do you worry about your newly developed products that will soon be duplicated by your market competitors yet?

If you are worried, you might consider developing some new connectors and new connectivity solutions, we only give you an exclusive supply. The unique connection between client and host allows you to firmly grasp the customers. For example, Apple company developed ligntning connector for his iPhone 5, iPhone 6, iPad series products, other competitors couldn't use this connector into their devices. Thus it prevent his customer from choosing other imitation.

Are you deeply troubled by finding the ideal connectors?

Sometimes, the standard connection solution may not be consistent with your requirements. Unique application and equipments are in needs of specially-made electric connector. But now the manufacturers and consumers have many different kinds of choice for electrical connectors, if you can't find the products that can meet your demand, you can choose to custom connectors. Customized connectors are specially designed and manufactured to comply with the concrete specifications you need, thus you can adjust the equipment's characteristic, performance, model and so on. You can make minor changes for existing products, and also can create new products. If you want us to develop a custom made connectors, you need to consider the following factors:

Complexity: the custom connector can be used by existing standard connector design and make a little change. Sometimes it needs to be fully customized unique design. we can create new features and design elements based on customer's application devices. So what uniqueness and complexity your custom connector will show?

Specifications and shapes: considering the width and length of the equipment , you can determine the applicable connector specifications. You can also design unique shape connector according to your equipment. What are your requirements for specifications and shapes?

Features: To take the characteristics of the equipment into consideration, Whether you need to use the connector in harsh environments? Whether you need to give priority to strength and durability? Whether you need to include the function of key design to prevent errors matching? Is it the crucial factors that the connector keeps matching and Docking(for example, whether it will use in the medical device concerning life and death for patients)?

Production cycle:you may have realized that the time of connector production is depended on the complexity of connector design. If you make a tiny change in standard connector, then two weeks delivery time (the time from submit orders to product delivery) should be enough. If the product needs to have many unique features, it will increase the difficulty of production, you may need to wait for three to five months.

Non-Recurring Engineering (NRE) : each product needs to have one-off research, development, design and testing costs, that is one-time project cost (NRE). As the same with production cycle, NRE is also depended on the complexity of custom products. If the change is bigger, cost is higher. If your budget is limited, you can discuss design requirements with manufacturer and see if there are any adjust to save cost.

Minimum Order Quantity(MOQ): if you want to buy customized connectors, so it is important to remember that, most companies have a higher MOQ (usually 100 pieces or more), but also there are some companies with a low minimum order quantity. Therefore, you may need to do some search to find a relatively loose company.

If you cannot find what you need a series of standard connector type, then you can create your own custom connectors!!!! You may need to spend some extra time and money, but in this way, you can ensure that the connector can perfectly match with your application equipments.

PCB Design & Manufacturing Services

The design of Printed circuit board (PCB) is based on the graph of electric circuit principle, then realize the function the circuit designer need. The design of the printed circuit board mainly refers to the layout design, need to consider various factors such as the layout of the external connections, the layout optimization of the internal electronic components, the layout optimization of metal wire and hole, electromagnetic protection, heat dissipation etc. Good landscape design can save production costs and achieve good circuit performance and heat dissipation performance. Simple layout design can be implemented by hand and complex layout design be achieved with the aid of computer aided design (CAD).

CAD 2D Proe 3D Drafting Services

CAD 2D / ProE 3D Drawing and Drafting Services described in FLECONN's Terms

What is CAD 2D Drawing and Drafting Services?

CAD 2D drawing/drafting services refer to drafting by surveying and mapping the sample from customer and providing corresponding two-dimensional view service, or to drawing and providing the corresponding two-dimensional view service according to the specific requirements of customers. Thus customers can carry out the design review, producing and processing products according to the 2D view.

CAD 2D drawing refers to respectively drawing the product shape or profile projection in the plane of x, y or x, z or y, z, and marking the length, width, height, then it can express a complete entity based on three view drawing and profile. Views can be cut to show a cross-section, a 2 dimensional view of the inside surfaces. Views can be shown looking down (plan view or top view) or facing the object (elevation or side view).

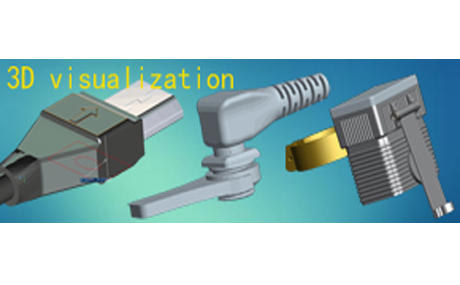

What is Proe 3D Drawing and Drafting Services?

Proe 3D drawing/drafting services refers to drafting and providing corresponding three-dimensional diagram by the sample or specific requirements from customers. 3D model can vividly show the ideas from customers, and it can be constantly improved according to the requirements of the customer until the customer is satisfied with the 3D drawing. For the internal structure of product, we can dissect cross-section and make customers have a complete understanding the internal structure of physical objects.

ProE 3D graphics software is a high performance 3D graphics software, it can provide x, y, z three coordinate views. You can view all kinds of size. At the same time, you can transfer Pro/E 3D Drawing into CAD 2D view, thus greatly save the time of drawing CAD 2D view. Once you complete 3D drafting, 2D view will come out. 3D graphics can effectively realize the communication between the originator of demand and product designer, product designer and production department, and reduce the differences in the communication.

Custom Plastic Enclosures/ Housings

Plastic electronic enclosures, plastic housings, plastic cases, plastic mould designing and manufacturing

FLECONN owns a plastic factory engaged in designing and manufacturing plastic electronic enclosures, plastic housings, plastic cases, plastic boxes, plastic mould. We can provide the schematic design of plastic product for our customers. Our rich experienced engineers can design an excellent product structure, product shape for world wide clients. We also provide free sample making, free customized scheme.

Plastic products design process

Determine the requirements of product functional and appearances

Draw a preliminary design

Make Prototype model

Product testing

check and correct the design

Formulate important specification

Open mold to produce

The quality control

Plastic products design principles

Determine the shape, size, appearance, material of the product in accordance with the product function.

Designed products must conform to the principle of molding, mold making is easy, forming and later processing is easy, but need to keep the product function.

Product design checklist, it will help to make sure the design of a variety of factors

General information:

What is the function of the product?

What is the required tolerance?

The consideration of space constraints ?

Define the working life of the product?

Consider product weight?

Have you acknowledged specifications?

Is there a ready similar application ?

Plastic products Structure:

The status of using the load?

The parameter size of working load?

The duration of using the load?

The allowance for deformation?

The environment

What is the using temperature environment?

The using or removing for chemicals or solvent?

What is the environment of temperature?

What is the service life in the using environment?

Plastic product Appearance:

Shape

Color

Surface processing such as texture, spray paint, etc

Economic factors:

What is the forecasted price?

What is the price of the product designed current?

The possibility of reducing costs?

Waterproof Enclosures/ Housing/ Box Design

The senior engineers in FLECONN own extreme rich experience in designing waterproof enclosures case and box for electronics products. Before designing water-resistant box and case, you need to figure out the use environment of the product.

Is the product used indoors or outdoors?

Will it be exposed to the rain or not?

Will it contact water or be submerged into water?

We need to determine waterproof level according to these application environments so as to achieve the purpose of use and also save cost. General waterproofing grade is between IP63 to IP68. It is divided into

IP63: there is no effect when water or rain water drops on the housing from 60 degrees corner;

IP64: there is not affect when liquid is splashed to the shell from any direction ;

IP65: wash the housing or shell with water without any harm;

IP66: it can be used inside the cabin environment;

IP67: it can be resistant to immerse in a short time (1 minute);

IP68: It can resist water when it is submerged under a certain water pressure for a long time, such as deep-water cable.

At right picture, a waterproof box is placed outdoor open air, which is equipped with electronic components, circuit boards, batteries, sensors, therefore, its waterproof protection rate needs to achieve IP67.

The bracket design for waterproof box

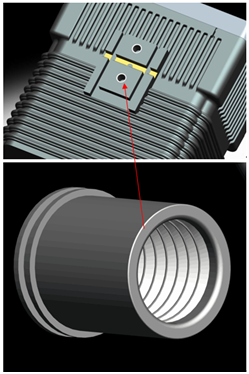

The waterproof box needs to be fixed on a circular column, we need to design an opening metal locking ring. The locking ring will be used to connect the waterproof case and the column. To make metal locking ring and waterproof box formed a solid connection, our design engineers did some professional design. They made some mutual matching groove design respectively in the waterproof box and the metal ring, and the metal nuts were built into the box body by nut embedded molding process. Therefore, the nuts and the box become one entity and won't not loose. Metal nut is not easy to slip teeth. After the connection between metal ring and case body is good, we can lock the metal ring on the box by screws, so that the screw can mainly withstand horizontal force, the matched groove structures can bear the vertical force.

The internal structure design for waterproof box

The internal of the waterproof case needs installing battery, PCB, sensor. Therefore, we need to carry out internal structural design according to the actual size of these components. At the same time, we need to consider the installion position of sensor by our customer re quirements.

Waterproof cover design

1. What is the fastening method between waterproof cover and box?

Using screws and embedded metal nuts come true the tight connection.

2. Which type of waterproof structure will be chosen?

First, we need to understand common waterproof design methods:

Seam Allowance method, waterproof ring method, ultrasonic method, secondary injection method, sealed and insulated circuit waterpoof design method.

When you design water resistant electronic products, you must make the water level of electronic products clear. Structural design methods are vary with waterproof grades. For example: the secondary injection waterproof design method can achieve IP8, Seam Allowance waterproof design method can only reach IP4.

We choose the combined waterproof design methods of Seam Allowance and waterproof ring. Thus the waterproof box can reach a higher waterproof level.

Precision Mould Manufacturing

FLECONN is mainly engaged in designing and manufacturing of plastic mould for electronic products, medical products, digital products, gifts, instruments and meters, electric appliance, automobile, toys products, the thermostat housing, remote control housing products, injection processing, mold processing, plastic injection mold etc. FLECONN owns complete and scientific quality management system. FLECONN's integrity, strength and product quality obtain industry acceptance. Welcome friends from all walks of life come to visit, guide, negotiate business.

1, Mold department has high-precision CNC mould processing and testing equipments such as high-speed CNC machining center, mirror spark machine, low-speed wire cutting, quadratic element and so on. Specific equipment: three CNC machining centers, 15 sets of milling machine, 3 sets of grinder, 6 sets of wire cutting machine , 5 sets of sparks machine, one set of quadratic element equipment, more than 30 sets of drilling and lathe machine and so on. The grinding precision of mould processing equipment is 0.002 mm, discharge precision is 0.005mm, wire cutting accuracy is 0.002 mm.

2, Since the company creation, innovation, attentively do a good job in every detail, adhere to conducting ourself and doing business with the basic principles "integrity, responsibility, enthusiasm". We are devoted to using technology to provide clients with better experience and service. hope constantly improve according to the customer's requirements, to provide satisfying products and services for customers, grow together with customers and achieve win to win!

3, Our company has independent research and development team, that can guarantee the customer product and mold design requirements, ensure to have new design and new product launch in each month in order to make preparation for the customers constantly opening up new markets. At the same time, That can effectively guarantee our partners' competition ability in the market. We provide product design and mold design, production, integration of electronic product assembly, enable customers to achieve one-stop shopping from mould to plastic electronic products.

4, The price of all products from our company has great advantages on the premise of the same raw material and product quality, but would you remind every customer can't use our price to compare with poor quality and low price products!

5, Quality assurance: our all mold products, plastic and electronic products are maden by the materials confirmed in the quotation, such as problems caused by the quality problem of the product material, we promise exchanging a purchase and undertaking freight!

6, We provide customizing mold, custom plastic products and electronic product housing by the samples from customers. You only need to provide confirmed drawings or samples, we will strictly produce according to your request and provide satisfactory products for you!

7, Delivery commitment: we commitment to strictly execute all production according to the production delivery requirements of the sales contract. If there is drawing changes in the production process cause the change of the delivery date, we will arrange very top time for changed schedule. At the same time, we need your cooperation to discuss detail information and reach an agreement on business demands by our schedule, or it is difficult for us to achieve the original delivery date.