Product Categories

Contact detail

- Mobile Phone:+86 13265562978

- Tel:+86 755-23490966

- Email:sales@fleconn-china.com

Chat Now:

DB15 Male to Female Cable, Connector with Plastic Assembly Backshell

E1005

DB15 Male to Female Cable, D-sub 15 pin Male to Female Connector Cable, Male D-sub 15 way to Female DB9 Extension Cable

FLECONN can custom db15 male to female cable, d-sub connector with plastic assembly backshell for industry equipment manufacturers.

Product Description

DB15 Male to Female Cable, Connector with Plastic Assembly Backshell

FLECONN can custom db15 male to female cable, d-sub connector with plastic assembly backshell for industry equipment manufacturers.

DB15 male to female connector cable assembly process

1 Cable assembly Parts

1.1 Cable

1. 15 core or greater 24AWG MINIMUM 10 STRANDS shielded, 350mm long

OR

2. 6-core 24AWG MINIMUM 10 STRANDS shielded, two lengths of 350mm to meet core count

required.

MULTICOMP SPC19822-RH (Element14 1846734) or equivalent

1.2 Termination J9 Parts (Electronics)

1. D Sub, DA, Plug, 15-way Solder

MULTICOMP 5501-15PA-02-F1 (Element14 108467301) or equivalent.

2. D Sub, DA, Backshell; Black, Nylon with manual screws

MULTICOMP MC-DPPK15-K (Element14 2346823) or equivalent.

1.3 Termination J10 Parts (Camera)

1. D Sub, DA, Receptacle, 15-way, Solder

FCI DA15S064TLF (Element14 2112356) or equivalent.

2. D Sub, DA, Backshell; Black, Nylon with manual screws

MULTICOMP MC-DPPK15-K (Element14 2346823) or equivalent

2 Assembly

2.1 Assembly J9

. Strip outer sleeve approx. 25mm.

. Twist drain/shield together.

. Strip cores wires over 2mm.

. Twist core wire ends.

. Add label “BOTTOM SENSOR” onto cable and cover with clear heatshrink.

. Solder core wires into D-sub solder cups.

. Put D-sub into shell.

. Attach strain relief. Ensure strain relief is applied on cable outer sleeve.

. Complete shell assembly with manual screws.

2.2 Assembly J10

. Strip outer sleeve approx. 25mm.

. Twist drain/shield together.

. Strip cores wires over 2mm.

. Twist core wire ends.

. Add label “BOTTOM SENSOR” onto cable and cover with clear heatshrink.

. Solder core wires into D-sub solder cups.

. Put D-sub into shell.

. Attach strain relief. Ensure strain relief is applied on cable outer sleeve.

. Complete shell assembly with manual screws.

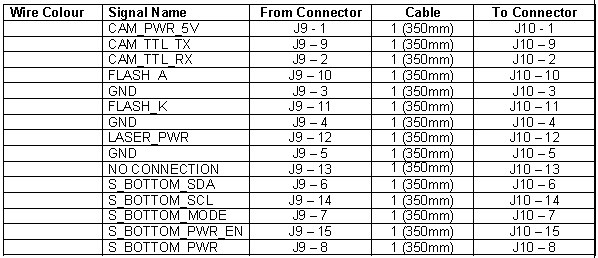

3. D-sub 15 Pin male to female connector wire connection diagram